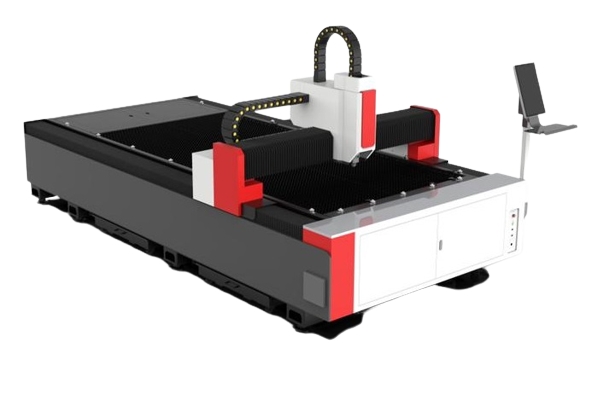

FIBER LASER CUTTING MACHINE

Super Heavy Steel Welding Machine

The bed adopts 12mm super-thick monolithic steel plate laser blanking. The groove welding method is used to make the plates reach equal strength butt Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the extremely high stability and cutting accuracy of the bed.

The Fifth Generation Aviation Aluminium Alloy Beam

The whole beam is processed by T6 heat treatment process to make the beam obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

Auto Focusing Laser Head

The auto-focusing optical fiber cutting head has a built-in motor drive unit. The focus lens is driven by a linear mechanism to automatically change the position within the specified range. The continuous focus can be set by the program to complete the rapid perforation of thick plates and automatically cut plates of different thicknesses and materials.

Intelligent Control System

CypCut plane cutting software is a set of software specially developed for the deep customization of the laser cutting industry, easy to use, rich in functions, suitable for various processing occasions.

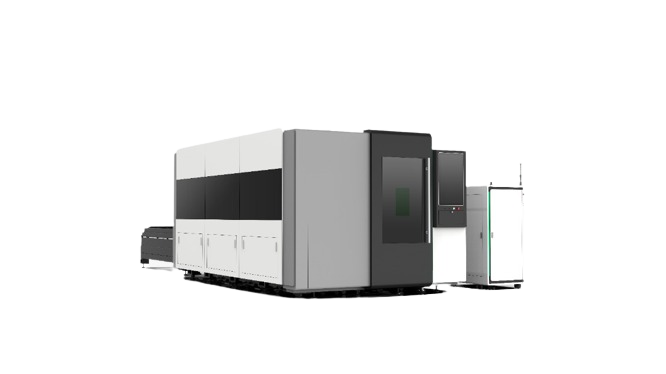

High Power Fiber Laser Cutting Machine

Full Protection Cover

Intelligent Monitoring

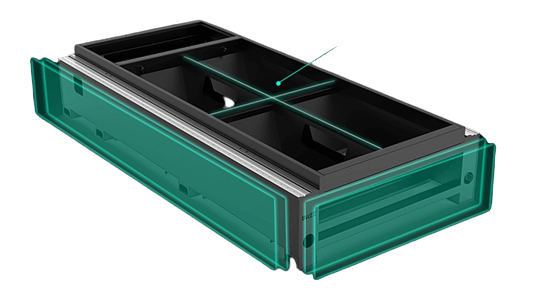

High and Low exchange platform, realize fast and complete exchange, save loading and unloading time

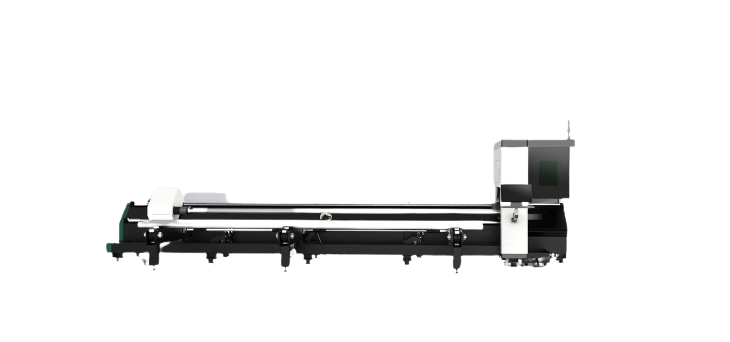

NL-TH6016 SERIES

side-mounted high-efficiency laser pipe cutting machine

Wide range of pipe cutting diameters Support cutting round pipe with diameter of f 15mm-f 160mm, square pipe with diagonal less than 160mm and shaped pipe.

Technical Parameters

Applications

Widely used in kitchen appliances, sheet metal chassis cabinets, mechanical equipment, electronic equipment, lighting hardware, advertising signs, auto parts, fitness equipment and other metal products, sheet metal cutting processing and other industries.